The new projects which are incomplete but on drawing board & under completion.

We at Shenoy Engineering, are currently developing an in-situ machine to chamfer and part tubes from 1/4″ to 5″. The salient features of this portable machine are: Can be operated by a single operator from start to finish. Eliminates operator fatigue by being electrically driven. A single Tube Bevelling & Parting machine to both cut.. read more →

Features & Specs: Rigid, heavily ribbed, fabricated and stress relieved structural. Atop the base, a servo driven rotary table is mounted which is dived into 8 stations. The fixture, will be designed to rest, locate on the ID. The clamping will be through pneumatic swing clamp cylinders. Station 1 will be loading station. This station.. read more →

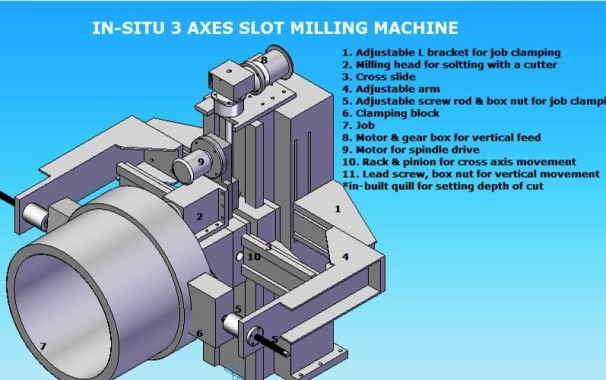

The 3 axes slot milling machine has a column which supports the cross slide and a slide for vertical movement. The Vertical Slide facilitates the up and down movement of the cross slide. A carriage on the cross slide houses the milling head. The milling head is driven by a standard gear box and motor… read more →

Flange manufacturing involves facing, OD turning, boring, in addition to pitch drilling for bolting holes. Instead of shifting the flange to different machines for these different machining operations, we have developed a SPM concept, which can do all these operations in a single setting. FEATURES: • Heavily ribbed base, on which a rotary table is.. read more →

Surfaces of huge square or rectangular flanges can be linear machined, using a in-situ X-Y axes machine. This is basically a vertical machine, mounted on the horizontally resting square tubes through hydraulic cylinders. The hydro-motor driven milling head, with its quill movement for depth of cut setting, is mounted on the cross beam. The milling.. read more →

Recent Posts

- 15 Jul 2017Tube Bevelling & Parting Machine

18 Jun 20168 Station Rotary table based Drilling and Chamfering SPM

18 Jun 20168 Station Rotary table based Drilling and Chamfering SPM- 28 Nov 2013Plano Millers on Sale

24 Apr 2013In-situ 3 Axes Slot Milling SPM

24 Apr 2013In-situ 3 Axes Slot Milling SPM 05 Oct 2012PayPal Integration

05 Oct 2012PayPal Integration