FAQ On Plano Milling Conversion

FAQ ON PLAON MILLING CONVERSION:

HOW A PLANER IS CONVERTED INTO A PLANOMILLER? After removing the existing tool post of the planer, on the same tool post carriage a milling head is mounted, perpendicular to the machine table. If your planer do not have a slow table speed, suitable for planomilling mode, an auxiliary table feed unit is inter-phased to the existing drive system of the planer.

Why Plano milling conversion?

Planomilling conversion of your planer drastically reduces the break down rates of your planer, since its speed is drastically reduced in planomilling mode and the cutting load is taken over by the newly introduced, self-powered milling head.

Planomilling conversion means increased productivity, as much as 10 times – no additional space; no additional manpower are required.

Is my old planer worth planomilling conversion?

Certainly yes. Planomilling conversion adds a new lease of life to your old planer. The slow table speeds in Plano milling mode and shifting of the cutting load from the machine drive system to the self-powered milling head certainly adds years into your old machine. The old planer, which otherwise should have been discarded sooner or later, gets a new lease of life and proves to be one of the most productive machines in your shop floor.

Is my new planer worth planomilling conversion?

Planomilling conversion simply enhances the life span of your machine by several times.

Is my small planer worth planomilling conversion?

We have converted as small planers as 4 ft long x 3 ft wide into planomillers and they have proved to be as productive as a No. 3 size vertical milling machine!

Is it expensive to convert my planer into planomiller?

You can convert your planer into planomiller for as little as Rs 1,00,000 including table feed system with our economy package. Batch production of milling heads have enabled us to offer you milling head almost at 10 years old price, inspite of steep increase in every input cost.

How fast can I get back my investment on planomilling conversion?

By the virtue of increased productivity of a converted planomiller, the investment on planomilling conversion has been earned back in less than a year in a number of industries.

Can I retain the planing capabilities of my planer after planomilling conversion?

Yes, it is possible. But we have never come across a single instance, where a customer has ever switched back to planing mode, after converting his planer into planomiller!

Can you do the conversion at my works?

Of course yes, but at an extra cost.

How shall I select a milling head?

Two factors are to be taken into account while selecting a suitable milling head – the maximum diameter of cutter you wish to deploy and the rigidity of the cross rail of your planer. For the generally available Indian make planing machines upto about 10 ft stroke length, 5 HP milling heads are the most suited ones. 5 HP milling head is suitable for mounting Ø125 to Ø 160 mm cutter.

What are these MHR series and MHCL series of milling heads?

MHR series milling heads are the time-tested and the most popular milling heads, specially designed for the week cross rails of Indian planers – to take the best from the combination of a slender planer and a robust milling head. Unlike in a milling machine, you don’t keep changing the spindle speeds and keep changing the cutters frequently. Cutter, once mounted on the spindle, will remain there for days and weeks at a stretch. Change gear pairs are provided with MHR series milling heads to achieve different spindle speeds, whenever you have to change the spindle speeds. MHR series milling heads are light in weight, amazingly robust and unbelievably cheap without compromising in the features.

Different spindle speeds in MHCL series milling heads are achieved through lever changing mechanism. These milling heads are ideally suited when changeovers of spindle speeds are very frequent.

What do you offer for the table feed and cross feed mechanism?

Mechanical Table Drive Units (MTDU) are the most economical solution for the table feed system in a converted planomiller. MTDU consists of a pair of reconditioned NISSAN or equivalent gearboxes and a 3 HP or 5 HP motor, which are neatly located in an elegant sheet metal enclosure. Lever changing mechanism provides 25 different stepped table speeds to the converted planomiller – right from 20 mm to 1000 mm per minute.

Mechanical Table Drive Units (MTDU) are the most economical solution for the table feed system in a converted planomiller. MTDU consists of a pair of reconditioned NISSAN or equivalent gearboxes and a 3 HP or 5 HP motor, which are neatly located in an elegant sheet metal enclosure. Lever changing mechanism provides 25 different stepped table speeds to the converted planomiller – right from 20 mm to 1000 mm per minute.

Electrical Table Drive Unit (ETDU) is a combination of worm reduction gearbox, motor and a frequency converter (VFD). A control panel houses all the switch gear elements for the milling head motor, table drive motor and the optionally offered cross feed unit and vertical feed unit. An operator pendant station with the required mechanical support houses all the controls and “mm per minute” digital indicator. User friendly, sleek and aesthetic, ETDU is certainly worth a little higher price tag. It provides stepless table speeds from 40 mm per minute to 1000 mm per minute to set the optimum cutting parameters. The controls on the operator’s pendant throws many operational advantages.

Through the same VFD of the ETDU, it is possible to control the cross feed unit (ideal for machining cross verse in table stationary position) and the vertical feed unit (ideal for vertical machining and drilling in table stationary position). It may be noted, being a common VFD, any one axis can be used at a given time through a selector switch mechanism, which is an in-built safety measure by itself.

Tell me about the right angle attachment

Right angle attachment, in combination with cross feed and vertical feed, adds floor boring capabilities to your converted planomiller! Jobs, which otherwise, should have been done in a floor borer, can be done in a converted plano miller.

Right angle attachment, in combination with cross feed and vertical feed, adds floor boring capabilities to your converted planomiller! Jobs, which otherwise, should have been done in a floor borer, can be done in a converted plano miller.

Right angle attachment has a Circular T slot based flange, which has a graduated collar. This enables you to set the spindle axis of the right angle attachment to any angle ?360?. In other words. You can machine all the 4 sides of a rectangular job in the same setting.

What is the advantage of the intermediary back plate?

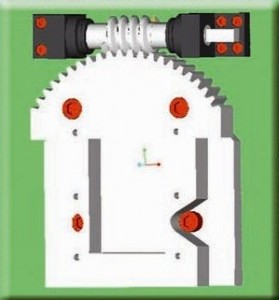

When introduced in between the tool post carriage of your planer and the seating base of the milling head, an intermediary back plate facilitates setting the spindle axis ?45?, so that you can machine the profiles like tapers etc. Back plate enables easy setting of the spindle axis with respect to the machine table in right angles. It also facilitates full utilization of the quill stroke of the milling head spindle. It is possible to mechanize the tilting mechanism through an integral sector gear and worm mechanism.

When introduced in between the tool post carriage of your planer and the seating base of the milling head, an intermediary back plate facilitates setting the spindle axis ?45?, so that you can machine the profiles like tapers etc. Back plate enables easy setting of the spindle axis with respect to the machine table in right angles. It also facilitates full utilization of the quill stroke of the milling head spindle. It is possible to mechanize the tilting mechanism through an integral sector gear and worm mechanism.

What is this Economy Milling Head, MHE-5?

The drive mechanism of the ECONOMY MILLING HEAD (MHE-5) consists of is a single stage reduction gearbox and a stepped timer pulley & belt mechanism. This milling head is without a quill movement and, therefore, it has to be mounted on the clapper box of the existing tool post of the planing machine. Using the same sliding mechanism of the tool post, you can set the depth of cut. The existing circular T slot based tilting mechanism in your tool post will continue to provide ± 45° the tilting mechanism to the milling head, after mounting the milling head. This milling head is designed specially for small jobbing shops, where investment is a constraint. MHE-5 is not suitable for heavy material removal from hard and work hardening type of metal. This milling head can also be used for mounting on the tool post carriages of lathes (for operations like slot milling, key way milling, peripheral drilling etc). Since this is a very robust and proven milling head, it can also be used in the milling and drilling SPMs.

How do you justify using of MHR series milling heads for general purpose Plano milling?

MHR series milling heads are all geared milling heads. They are the most rugged and well proven. MHR series milling heads are with 6 stepped spindle speeds and these speeds are achieved through change gear pairs provided. Change gear method helps to reduce the weight and the price of the milling head. Since changing of the cutter is not frequent in a planomiller (like in a milling machine), users do not feel it inconvenient to change the spindle speeds through change gear pairs.

Tell me about MHCL series milling heads.

MHCL milling heads are with 4 spindle speeds and you can select the required spindle speed through a convenient lever changing method.

What information should I furnish to get an offer?

1. Make and size of your planning machine

2. What is the max dia of cutter you wish to deploy?

- DRIVE FOR MHE-5 is through the combination of a pair of spur gears & time belt & pulley.

- DRIVE FOR MHR series milling head is through gear change method – helical bull & mating gears.

- DRIVE FOR MHCL series milling head is through lever change method – helical bull & mating gears.

- Case hardened & ground vital parts like gears, shafts, spindle, quill etc .

- Automatic lubrication system for the gear box.

- Ground splines for max contact area Molybdenum sulfide grease (lubrication for life) for spindle bearings.

- Spindle run out: 10 microns on OD, ID & face.

- Correct pre-loading of the spindle bearings Helical bull & mating gears Close fitment between the quill & the housing 4 taper roller bearings + 1 cylindrical roller bearings, total 5 bearings rigidly support the spindle and the bull gear.

- Reputed make of motors like NGEF, ABB, KEC Over 2000 milling heads working in India & abroad